New technology in mining, once implemented, serves as a basis from which even newer ideas become possible, according to Jean-Jacques Verhaeghe, programme manager of real-time information management systems at the Mandela Mining Precinct (MMP), the public-private partnership between South Africa’s Department of Science and Innovation and the Minerals Council South Africa (MCSA). And by sparking those even newer ideas, new tech enables ‘step and leap’ change, he says. ‘Look at the big tech companies, where technology and technical success perpetuates or constantly feeds new ideas into a system created for it, from which problems are solved with snowball effect.’

The global mining sector is at the cutting edge of such innovation and technology. Africa recently saw some revolutionary tech being launched, notably the world’s first hydrogen-powered mining truck and blockchain end-to-end tracking of diamonds (which is now also being piloted for cobalt by Glencore). There is more in the pipeline, as drones, AI, IoT and digital twins have already become a reality in some of the continent’s mines.

At the MMP in Johannesburg, technology development forms a core part of the mission. Through its collaborations with industry and R&D partners, the precinct works on mining-technology solutions that are implementable and relevant to industry needs – for instance, two new rock drills that were developed during the first open innovation challenge.

The prototype drills by local original equipment manufacturers Novatek and HPE are faster, more efficient and, importantly, safer than conventional rock drills, according to MMP director Johan le Roux. ‘Both the rock drills are ready for commercialised uptake, and the manufacturers have started to receive orders from mining companies.’

The precinct has also developed the first prototype of a remote explosives-charging unit, in partnership with the University of Pretoria. Mining Weekly reports that the unit is suited for low-profile operations, enabling operators to sit about 2m away from the working face in a supported area, meaning mineworkers no longer need to be directly exposed to the resulting dust and moisture.

Meanwhile, the MMP’s mechanised mining systems research programme has successfully tested and proven the effectiveness of real-time monitoring for ventilation-on-demand. Historically, mines were ventilated continuously, at huge expense, to provide fresh, cool air, and to dilute and remove flammable gases as well as machine exhaust gases.

‘Ventilation-on-demand refers to a practice where ventilating air is supplied to areas only when needed. Where no work is taking place, no air or a minimum volume of air is supplied,’ says Le Roux. This can significantly reduce the mine’s energy consumption while still maintaining good ventilation standards for workers. According to the MMP, ‘real-time in-situ condition monitoring with hazard-alarm notification, guided by people and equipment tracking, gives the control-room operator cutting-edge technology to proactively respond and action preventative measures to reduce risk to people, the environment, and equipment’.

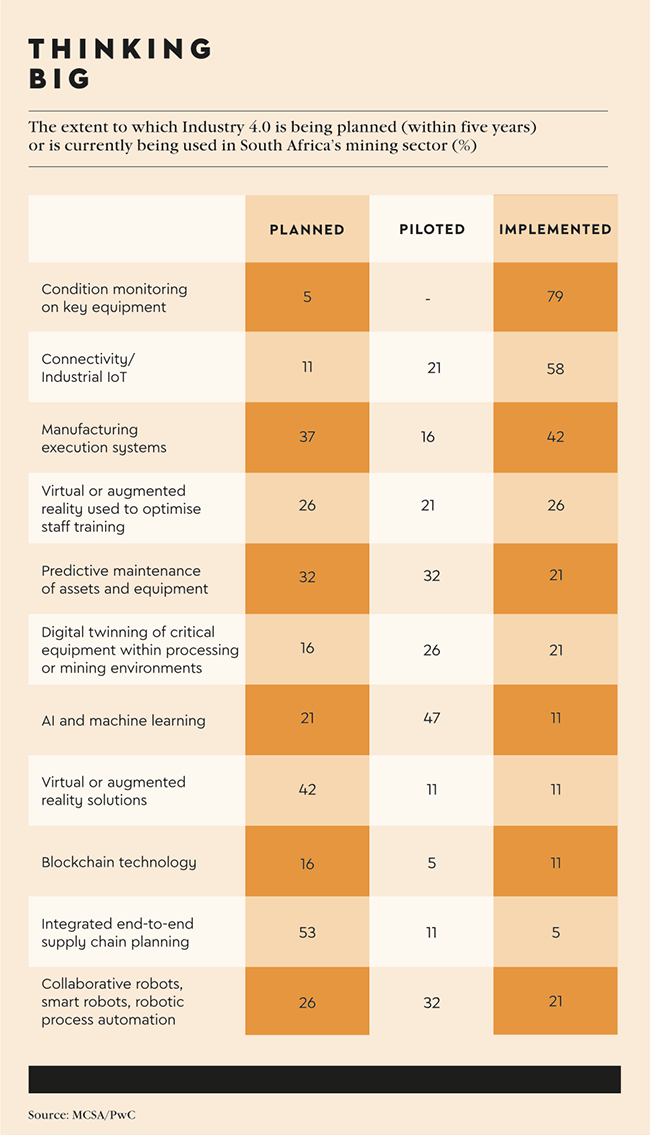

Environmental and social concerns play an important role in the adoption of new tech in mining, and the leading mining companies have embedded ESG in their innovation strategy. Interestingly, a 2021 study on digital transformation, by the MCSA and PwC, revealed that some South African mining companies consider themselves digital champions and innovators that will pilot new technologies without waiting for others to prove it first. The study says that, in fact, all South African mines are by their very nature innovative and tech-savvy, simply by virtue of the ‘hard rock, seismicity, extreme depth and the conditions under which we mine’.

Quoting an MCSA member, it adds that ‘anybody that can mine hard rock over 4 km deep and bring it back to surface at a profit is an extremely good innovator’.

The MMP’s Verhaeghe, who provided his expertise for the MCSA/PwC study, gives some examples of what he considers to be recent tech solutions that have the potential to spark ‘step and leap’ change in mining.

One of these is visual AI to monitor conveyor belts for production – to keep the ore flowing without interruptions – as well as to improve the safety for those working at or near the belts. This is part of efforts to visualise and manage operations in near real-time, in order to respond quickly and reduce costly stoppage time to improve productivity.

‘For a coal mine using an underground conveyor belt in the process of coal transmission, a lack of real-time monitoring and poor communication could mean that the organisation is unaware that the conveyor belt, which covers a long distance, is at certain times carrying a zero load, which could even stretch to hours,’ says Stephanie Rosenmayer, business unit manager at ICT solutions and managed-services provider Datacentrix. ‘This means that where there is no load, the mine is consuming power, and paying for it, at a time when it is completely unnecessary.’ At other times, the conveyor belt could be obstructed by foreign objects or oversized ore. People could be approaching the belt when they shouldn’t be, or the belt could be damaged, she explains.

International case studies of mines using AI technologies show a reduced conveyor belt downtime (from three days per month to one) with the ‘no-load’ power consumption also dropping (from US$650 000 to US$280 000 per year), she says. The other benefits of using visual AI monitoring include the ability to anticipate major risks, identify personnel violations and contain severe accidents. ‘They also now have access to intuitive measures for mining-operation supervision; reliable evidence for accidents in retrospection; and can provide statistical reporting on abnormal mining operations to support scientific decision-making.’

It’s widely understood that the future of mining lies in mechanisation, automation and digitalisation, where mines will be run from remote operation centres. Therefore, it is important that any new technology fits into the bigger system, allowing the total integration of data and work processes so that these can be managed in real-time and across multiple sites. In line with this, Verhaeghe says that another recent tech solution relates to ‘integration – consolidation – platform systems for enabling man-to-machine, machine-to-man, environment-to-man – and vice versa, environment-to-machine – and vice versa… All these interactions and data-sharing on common systems is possible’.

His third tech solution with ‘step and leap’ potential are ‘innovative and combination/hybrid solutions for underground communications, connecting old legacy systems to new, such as WiFi 6 to DSL’. The reasoning for this is that real-time communication is crucial, underground and above. Verhaeghe explains that such communication systems make prediction and, importantly, the ability to respond instantly possible.

‘Safety practices and processes can be analysed, and these trends and patterns can then be addressed, redefined and or optimised for the future.’ He adds that data itself presents new opportunities for revenue generating, and ‘blue-sky’ thinking and problem-solving.

‘Digitalisation and transformation will be a perpetual reality for the foreseeable future,’ he says. ‘5G is being tested at a minimum of three sites that I know of in South Africa.’ The region’s first 5G-enabled smart mine is currently being built in Limpopo, where MTN and Huawei signed an agreement with the Chinese Zijin group.

The Garatau platinum mine will increase competitiveness as 5G enables real-time remote control of machinery such as drones, while IoT sensors can be connected across the facility, both above and underground to enable asset monitoring and autonomous haulage.

According to Deloitte, 5G networks have the potential to save mining companies up to 20% in energy consumption while improving drill-rig operations by up to 40% and ore production by up to 25%, as a result of the superior network coverage, lower latency and higher reliability at every stage of the business operation.

Yet new tech also brings along new risks, as mining companies need to have viable use cases and prove its contribution to the bottom line. Or, as Verhaege puts it, ‘it’s about visionary mindsets, and managing complexity and plurality, and challenging contemporary engineering – in other words, evolutionary engineering that drives the ability to design, develop and implement future-proof technologies and at scale’.